Measurably precise

Innovative technologies secure your lead in digitalisation

Modern measuring techniques record physical data from various processes during a production operation – comprehensive digital information that you urgently need as a basis for achieving the Industry 4.0 standard. Based on industrial image processing, our measurements are contact free and precise. Pipe end measurements, straightness measurements, profile section measurements, curvature measurements or our 3D measuring system for bent pipes – we evaluate possibilities, test relevant configurations and select the optimal measuring technology for your needs. For example, the GMS-E, which has proven its worth since 2005, reliably supplies the required measuring results even under difficult conditions. The measurement is independent of the material.

- Product area

- Material

- Inspection criterions

Product area

- Keine Angabe

- Automotive round pipe

- Linepipe

- Construction pipe

- Steel profiles

- Continuous casting profiles

- Profiled rod products

- Curved pipes (e.g. hydraulic pipes)

- Curved rod material (e.g. Coil springs)

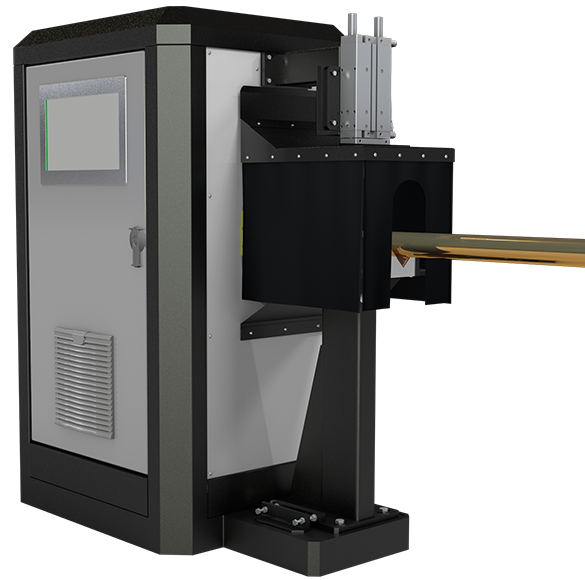

GMS-E

Pipe end measurement

The GMS-E is developed for industrial suited applications and provides information of the cross-shape of tubes, profiles and pipes.

Technical details

- Product areas: Automotive round pipe, Linepipe (LSAW, HSAW, Seamless), Construction pipe, Profiled rod products, Miscellaneous

- The measuring speed is configuration dependent.

- The measuring accuracy is up to 10µm.

GMS-S

Straightness measurement

The patented GMS-S enables the inline measurement of the straightness and twist of profiled rod products.

Technical details

- Product areas: Automotive round pipe, Linepipe (LSAW, HSAW, Seamless), Construction pipe, Profiled rod products, Steel profiles

- The measuring speed is 200Hz.

- The measuring accuracy is up to 100µm.

GMS-P

Outside profile section measurement

The GMS-P generates a digital image (Digital Twin) of the outer contour of profiles and pipes.

Technical details

- Product areas: Automotive round pipe, Linepipe (LSAW, HSAW, Seamless), Construction pipe, Profiled rod products

- The measuring speed is up to 1000Hz.

- The measuring accuracy is up to 50µm.

GMS-I

Inside profile section measurement

The GMS-I provides information concerning the internal contour of pipes. Even on high reflective surfaces.

Technical details

- Product areas: Linepipe (LSAW, HSAW, Seamless), Construction pipe

- The measuring speed is 200Hz.

- The measuring accuracy is up to 50µm.

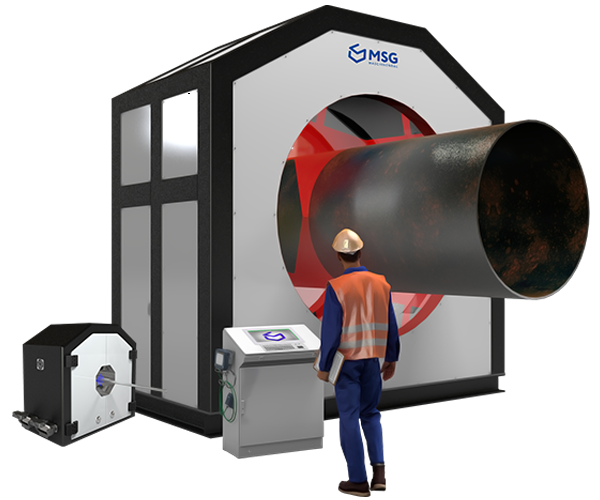

GMS-C

Curvature measurement

To monitor the curvature of a bent metal plate, the bending shape can be recorded with the GMS-C for comparison with a stored reference geometry.

Technical details

- Product areas: Linepipe (LSAW, HSAW, Seamless), Construction pipe

- The measuring speed is 200Hz.

- The measuring accuracy is up to 10µm.

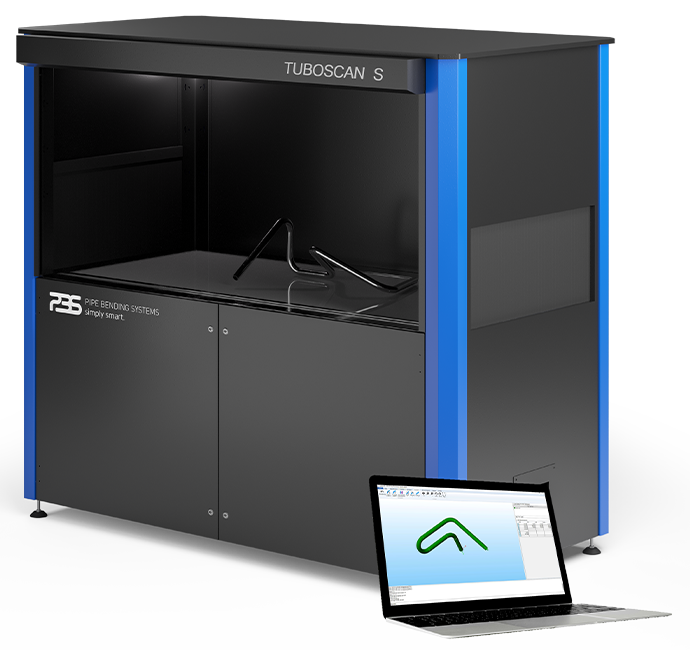

Tuboscan

Pipe measurement at lightning speed

The optical measuring system TUBOSCAN is able to precisely identify the geometrical data of pipe figures within a few seconds.

Technical details

- Product areas: Curved pipes (e.g. hydraulic pipes), Curved rod material (e.g. Coil springs)

- The measuring speed is 5 Seconds/Part.

- The measuring accuracy is ± 0,1mm.

SES

Surface Evaluation System

The SES offers the possibility to objectively recognize 3D structures on material surfaces and to evaluate them with regard to specific quality characteristics.

Technical details

- Produktbereiche: Automotive round pipe, Profiled rod products, Steel profiles, Continuous casting profiles