GMS-E

Profiler cross section

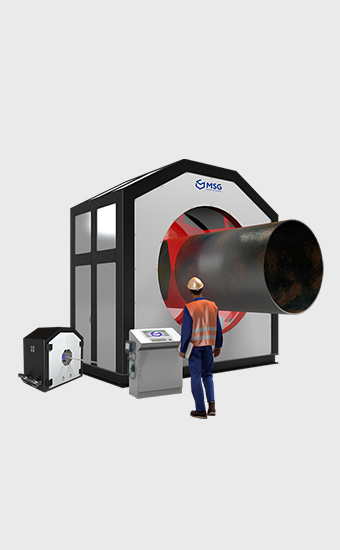

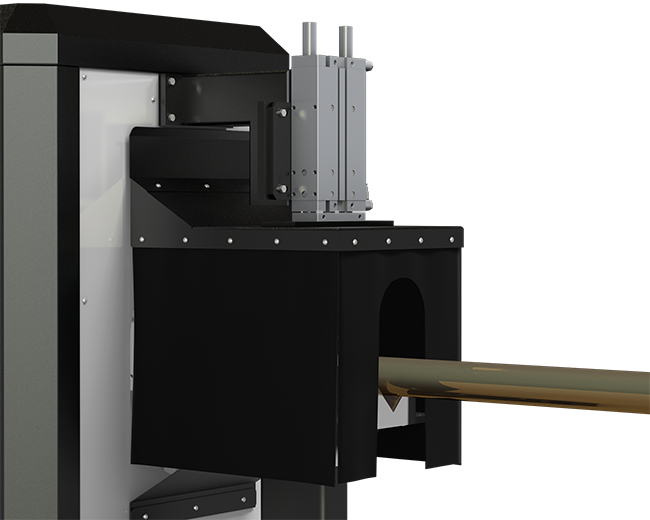

The GMS-E is developed for industrial suited applications and provides information of the cross-shape of tubes, profiles and pipes.

Measurably precise

The perfect result in one turn

In the early manufacturing process, drawn or sawn pipes in particular have deformations and burrs at their ends. Since the GMS-E measures the cross-section geometry far inside the pipe without ever establishing contact, unlike with conventional methods, such imperfections do not influence the measurement result. This way, the GMS-E can be used very early in the production process. The earlier the product quality is known, the less waste is produced!

Digital benefits of measured data

In addition to the digitization of your product geometry, specific inspection characteristics can be extracted with the GMS-E software and passed on for further processing via various interfaces to both the process control and operations control levels.

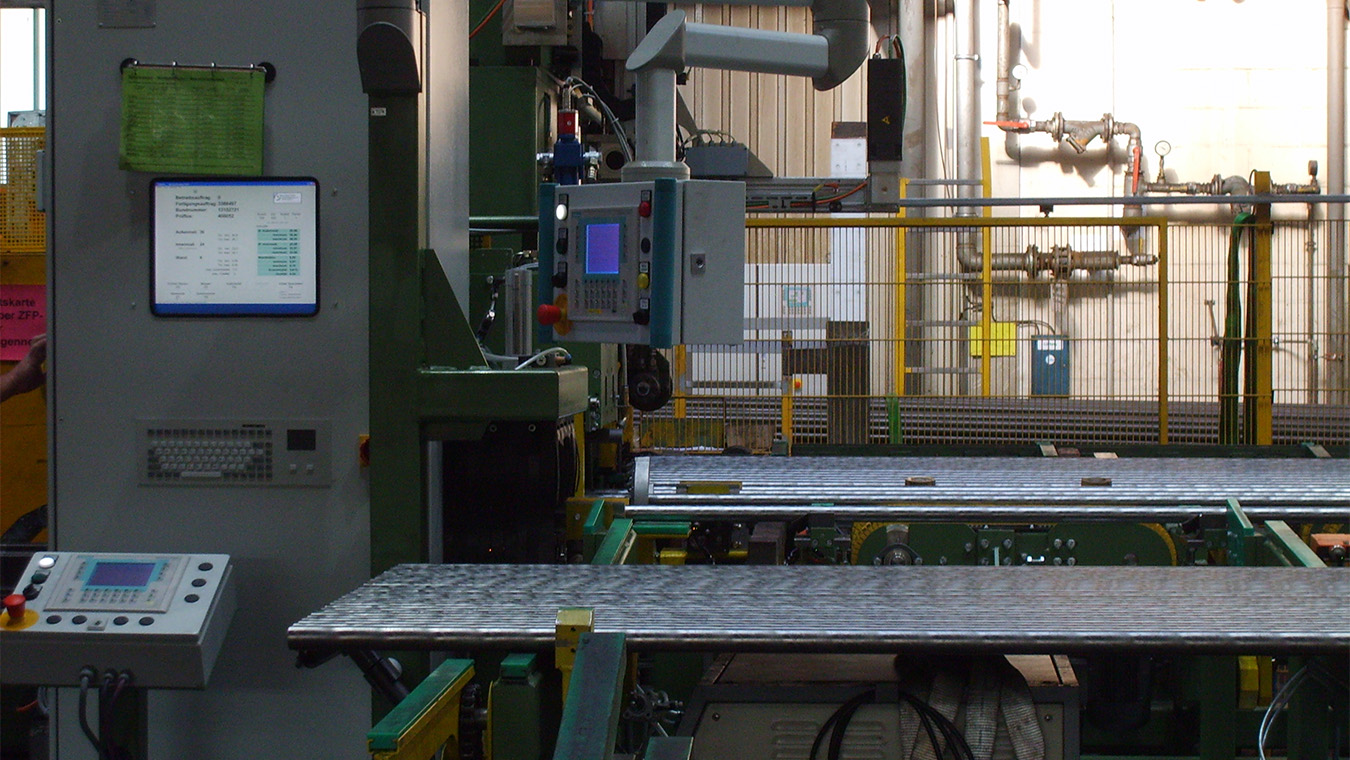

Implementation for industrial applications

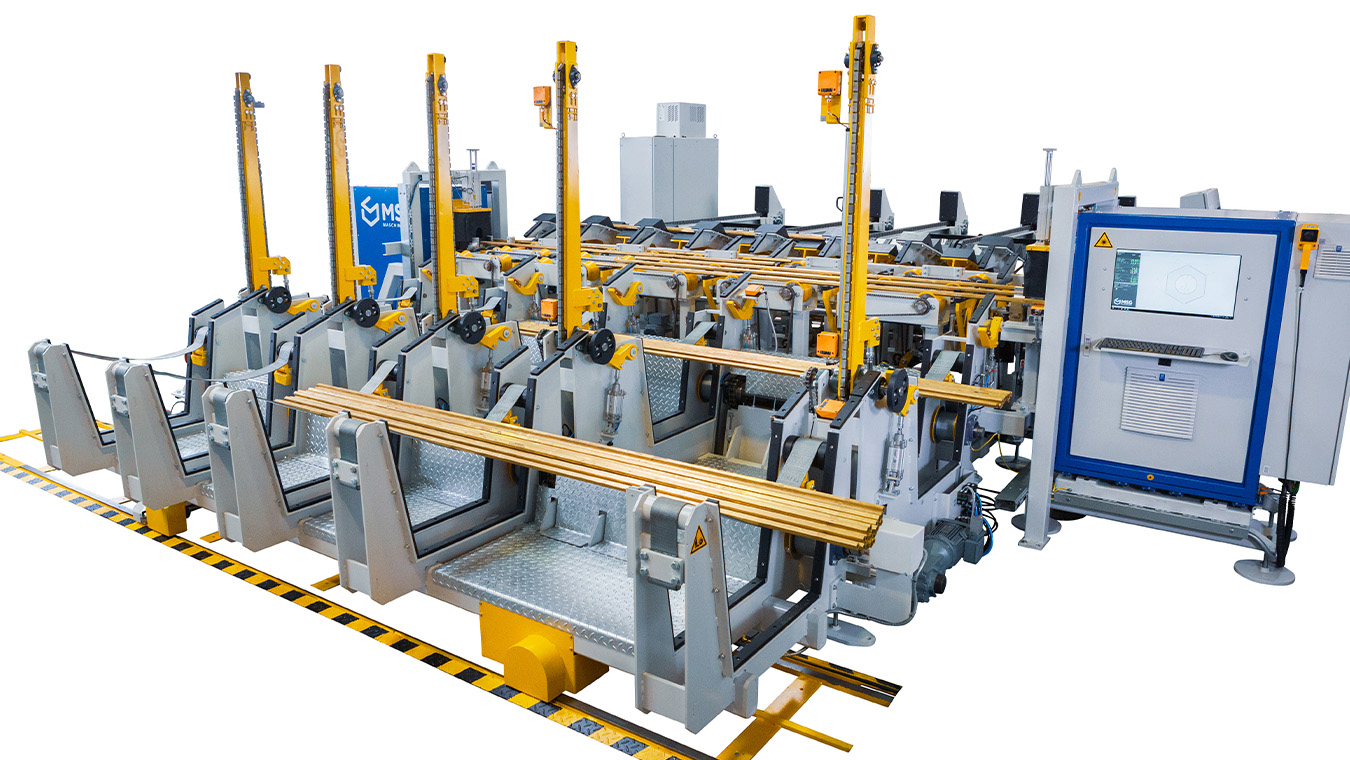

Thanks to our many years of know-how in mechanical engineering, especially for the semi-finished product industry, adverse environmental conditions are not an obstacle for us, but rather lessons learned that are taken into account in the GMS-E. Be it cross transport or axial feed – the GMS-E can be easily integrated at various points in your production line thanks to its intelligent design.

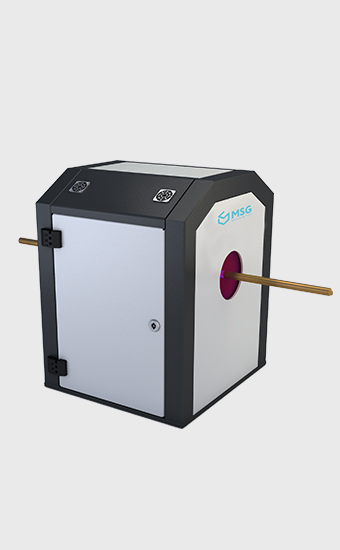

Mechanical adaptability

Our measuring systems are functionally standardised. This means that the measurement function is recurrently the same. The mechanical design, on the other hand, we adapt from project to project according to your circumstances. E.g. the rotation measuring head may be equipped with a second triangulation laser from a diameter larger than 200 mm.

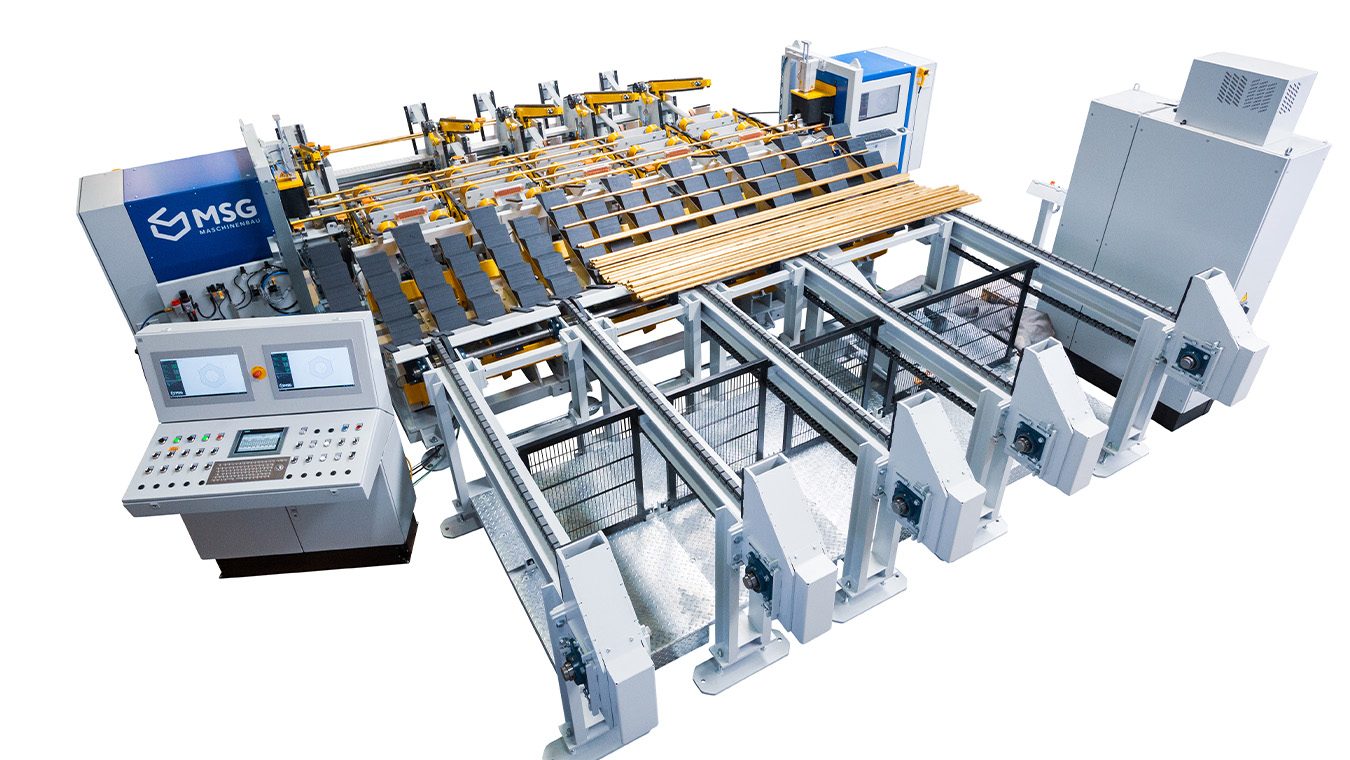

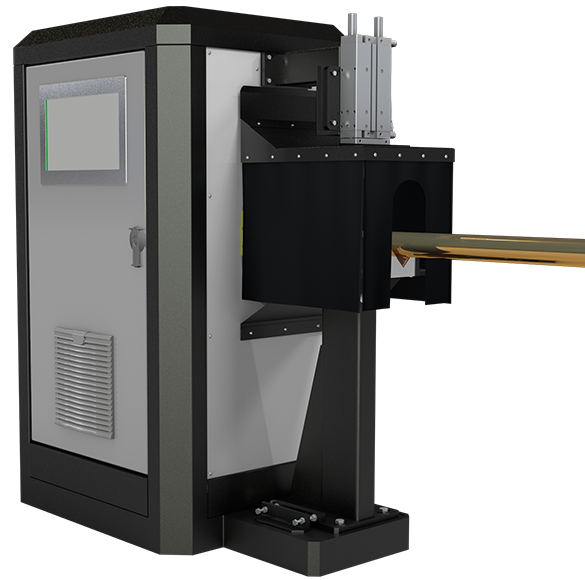

Use case

For final quality assurance, a fully automatic test line was delivered to Germany’s largest manufacturer of brass profiles. Here, both round and profiled products are inspected on a single system and sorted according to their quality.

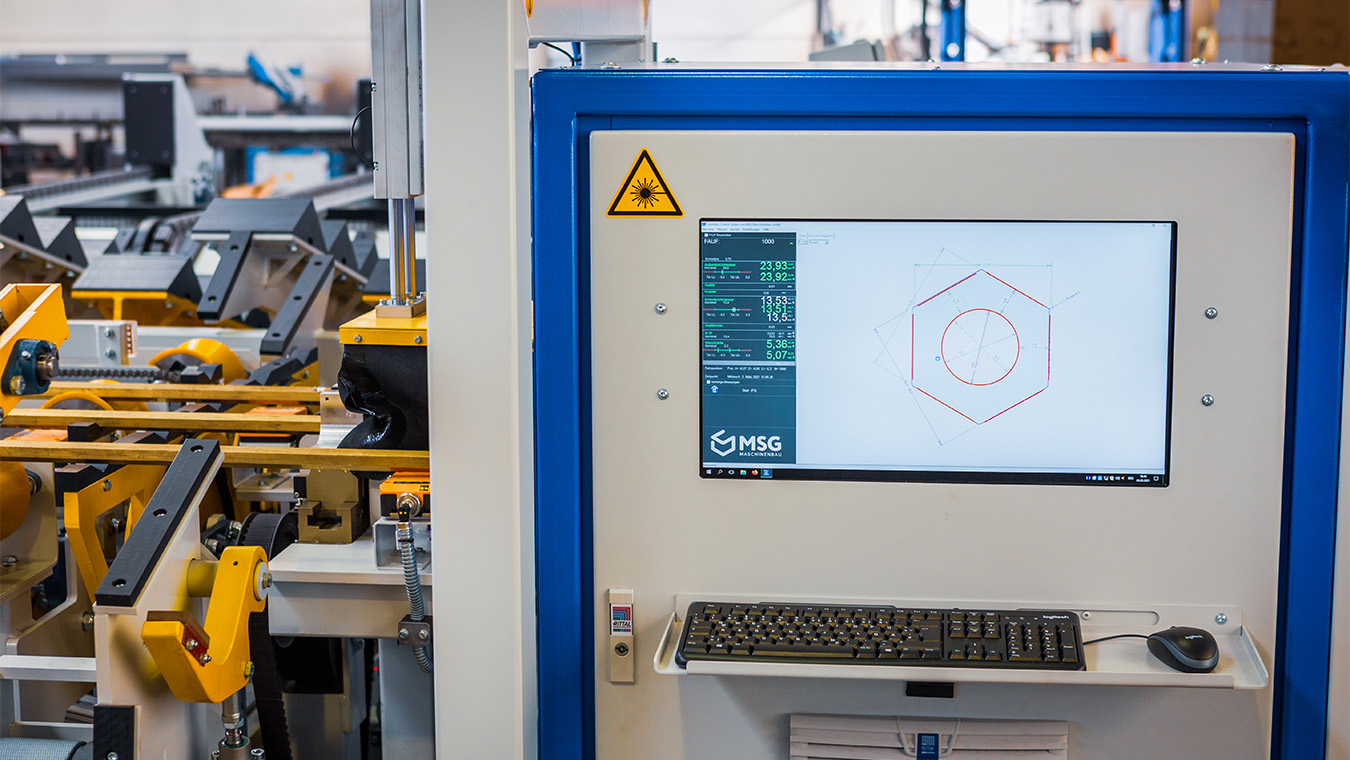

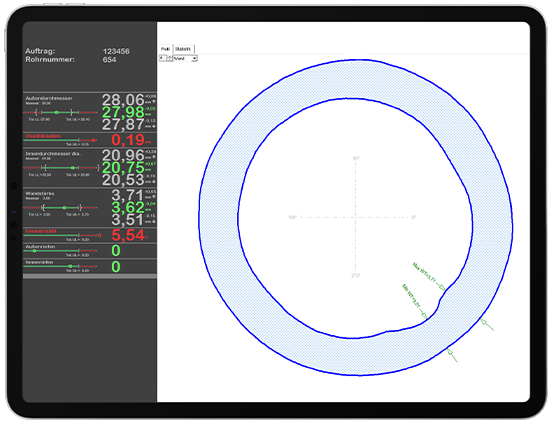

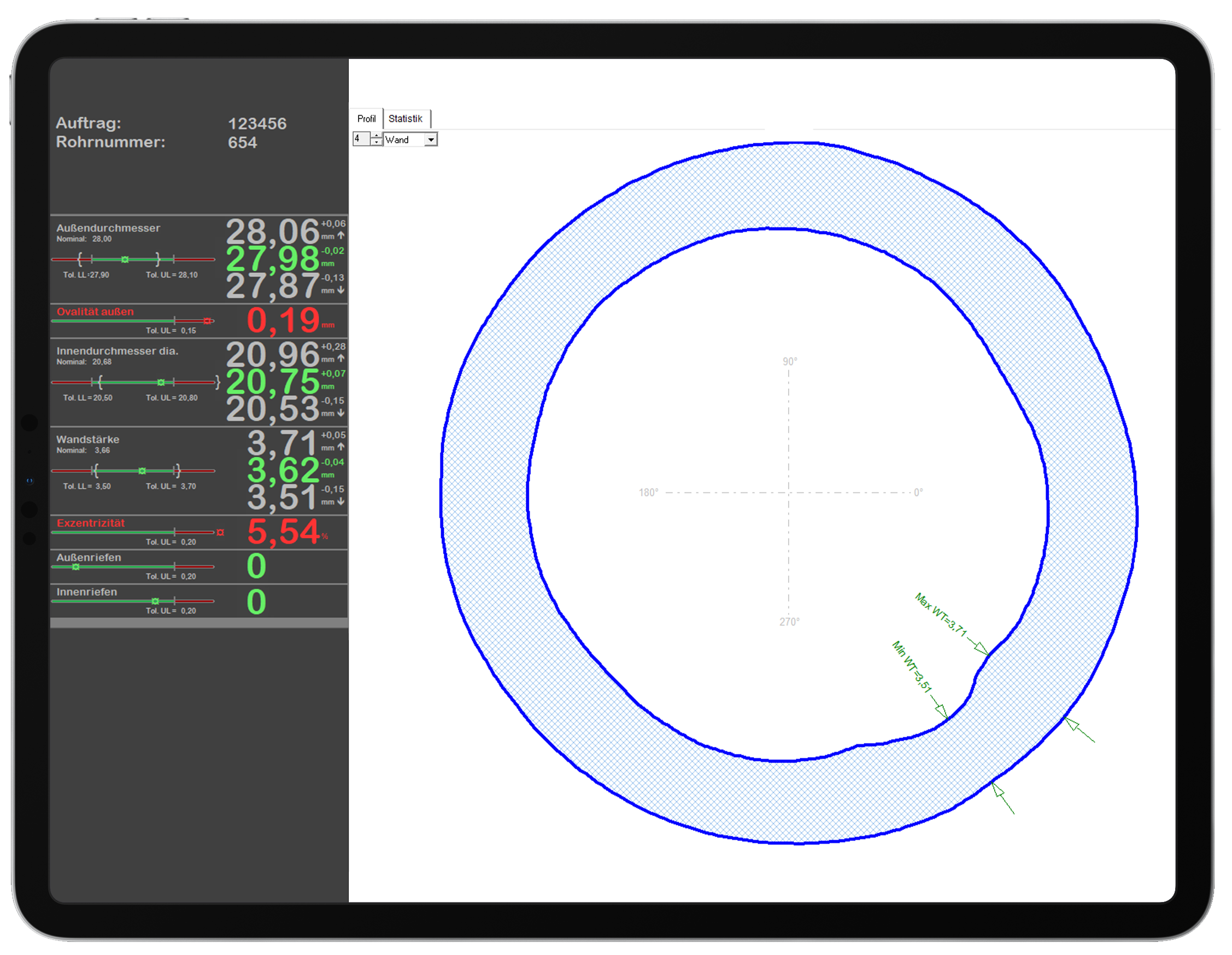

Outer diameter maximum, averaged, minimum

Ovality of the outer contour

Inner diameter maximum, averaged, minimum

Wall thickness Maximum, averaged, minimum

Coaxiality/ Eccentricity

View Change from Profile View to Statistical View

2D view scaling option

Outer contour

Minimum Wall thickness

Maximum Wall thickness

Inner contour

With the visualisation of your digital data, you always stay on top of things and can use the information for further processing.

Technical data

Application range

- Digitization

- Product certification

- System control

- Production optimisation in drawing machines

- Production optimisation in welding lines

- Machine Learning

Product areas

- Automotive round pipe

- Linepipe (LSAW, HSAW, Seamless)

- Construction pipe

- Profiled rod products

- Miscellaneous

Materials

- Steel

- Brass

- Aluminium

- Titanium

- Plastic

- a.o.

Integration possibilities

- Longitudinal transport

- Cross transport

- Standalone

Inspection criterions

- Outer diameter/radius

- Inner diameter/radius

- Circumference

- Ovality

- Local eccentricity

- Wall thickness

- Eccentricity

- Coaxiality

- Surface area

- Volume

- Weld seam height

- Weld seam width

- General weld seam shape

Measuring speed

- Depending on configuration

Measuring accuracy

- Up to 10µm

Interface

- Process: PLC

- Data: SQL

Machine dimensions

The standard system (max. Ø 60 mm) has approximate dimensions of 1000 mm height, 500 mm width and a depth of 500 mm.

Downloads

Data Sheet (EN)

Data Sheet (DE)

01/06

Similar machines

Take advantage of our know-how and experience to get one step ahead of the competition. Find more solutions here.