GMS-S

Straightness and twist measurement

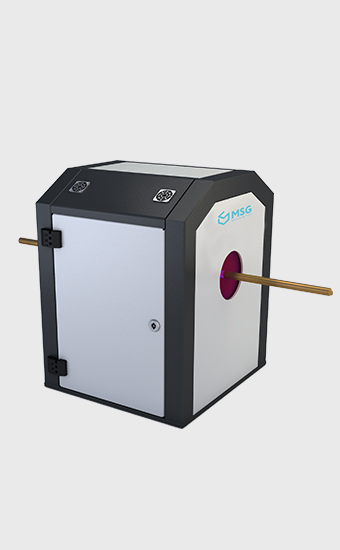

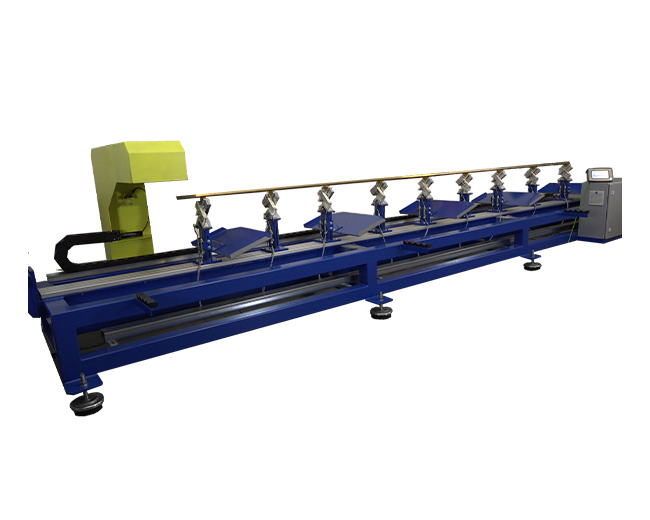

The patented GMS-S enables the inline measurement of the straightness and twist of profiled rod products.

Measurably precise

It doesn’t get more objective than that!

The patented GMS-S allows for a 100% inline measurement of the unambiguous and effective straightness and twist of rod products. The known measurement deviation of conventional test methods, caused by existing constraining and static friction forces in workpiece fixtures, centrifugal forces in rotating test systems or the scatter of the subjective operator assessment, are completely eliminated by the GMS-S. The measuring result is comparable to a survey with zero gravity!

Digital benefits of measured data

DBy digitising the unambiguous product straightness, upstream or downstream manufacturing processes can be evaluated immediately or optimised in the aftermath by machine learning algorithms. The superordinate added value is the reduction of production costs.

Implementation for industrial applications

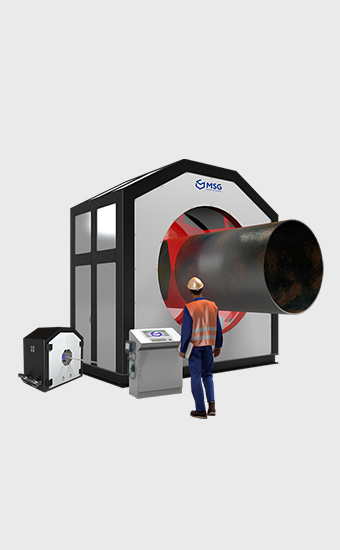

Thanks to our many years of expertise in mechanical engineering, especially for the semi-finished products industry, adverse environmental conditions are not an obstacle for us, but experience that has been incorporated into the GMS-S product. For example, vibrations introduced into the measuring nuit or workpiece are absorbed by an intelligent damping system. Depending on your production architecture, we integrate the GMS-S with various adjustment solutions. Lifting your products into the GMS-S or lifting the workpiece out of an existing chain conveyor are just two implementation approaches.

Mechanical adaptability

Whether linear moving, swiveling or statically installed contour scanners - the digitization technology of the workpiece contour is selected together with you on the basis of our many years of independent expertise based on your production environment.

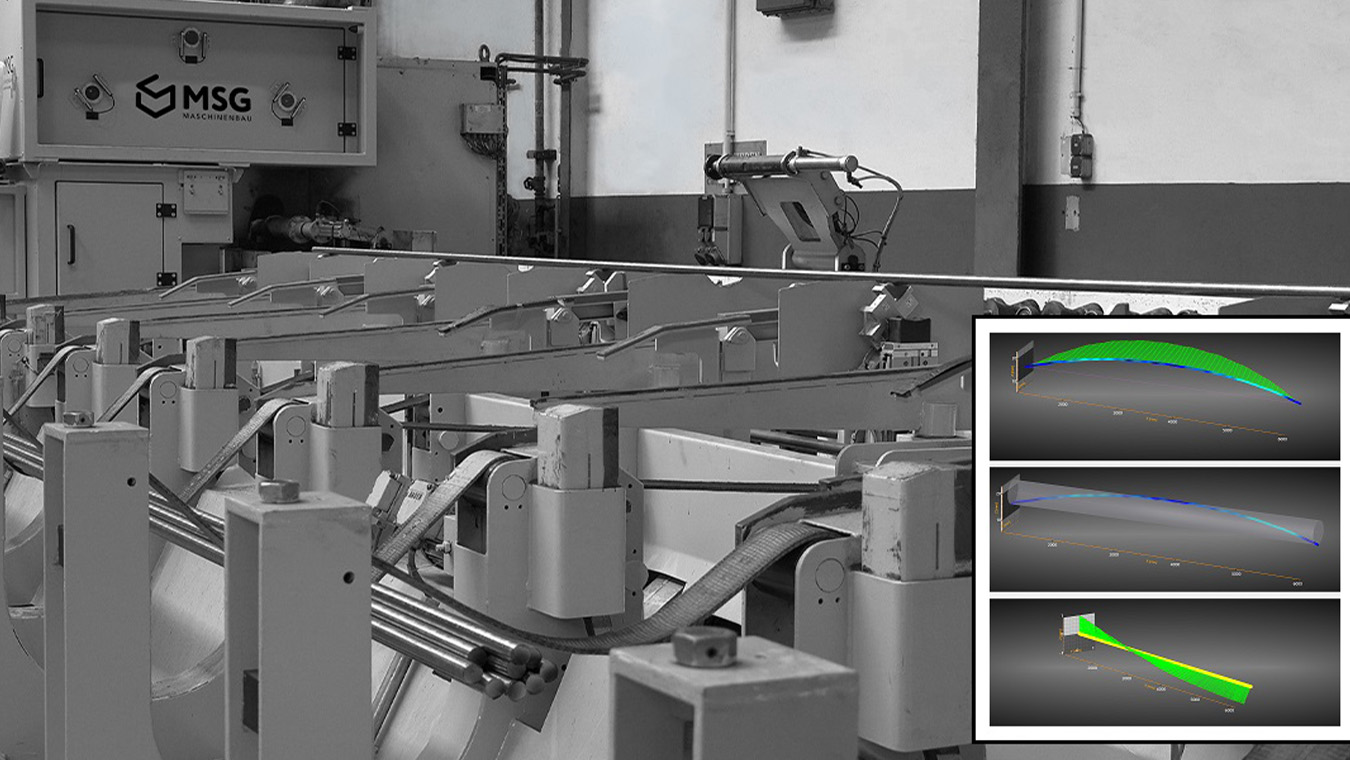

Use case

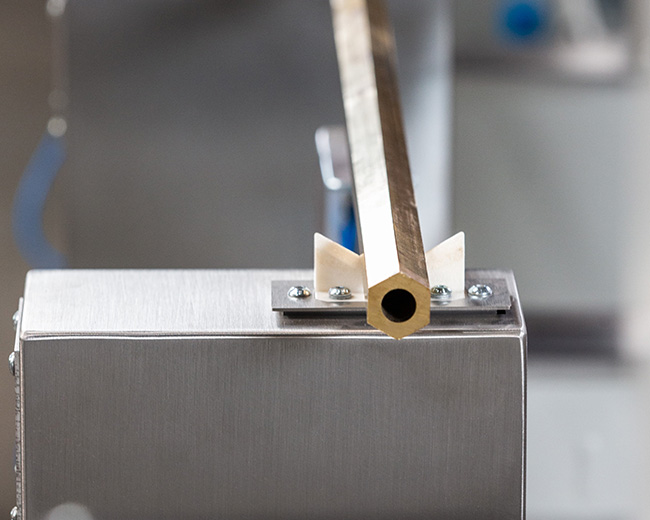

The GMS-S was used to control the production quality of brass profiles in a continuous target line by ASMAG GmbH. The result: Objective measurement results in a cycle time of less than 2 seconds!

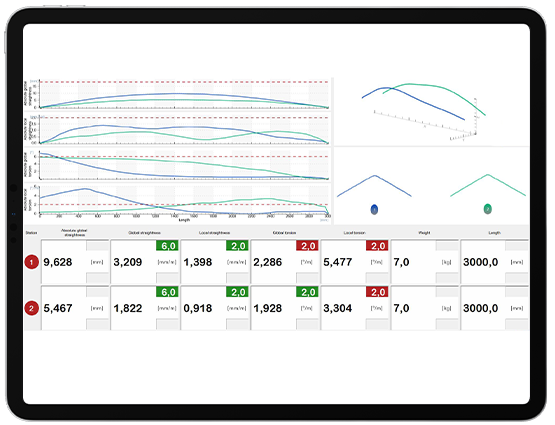

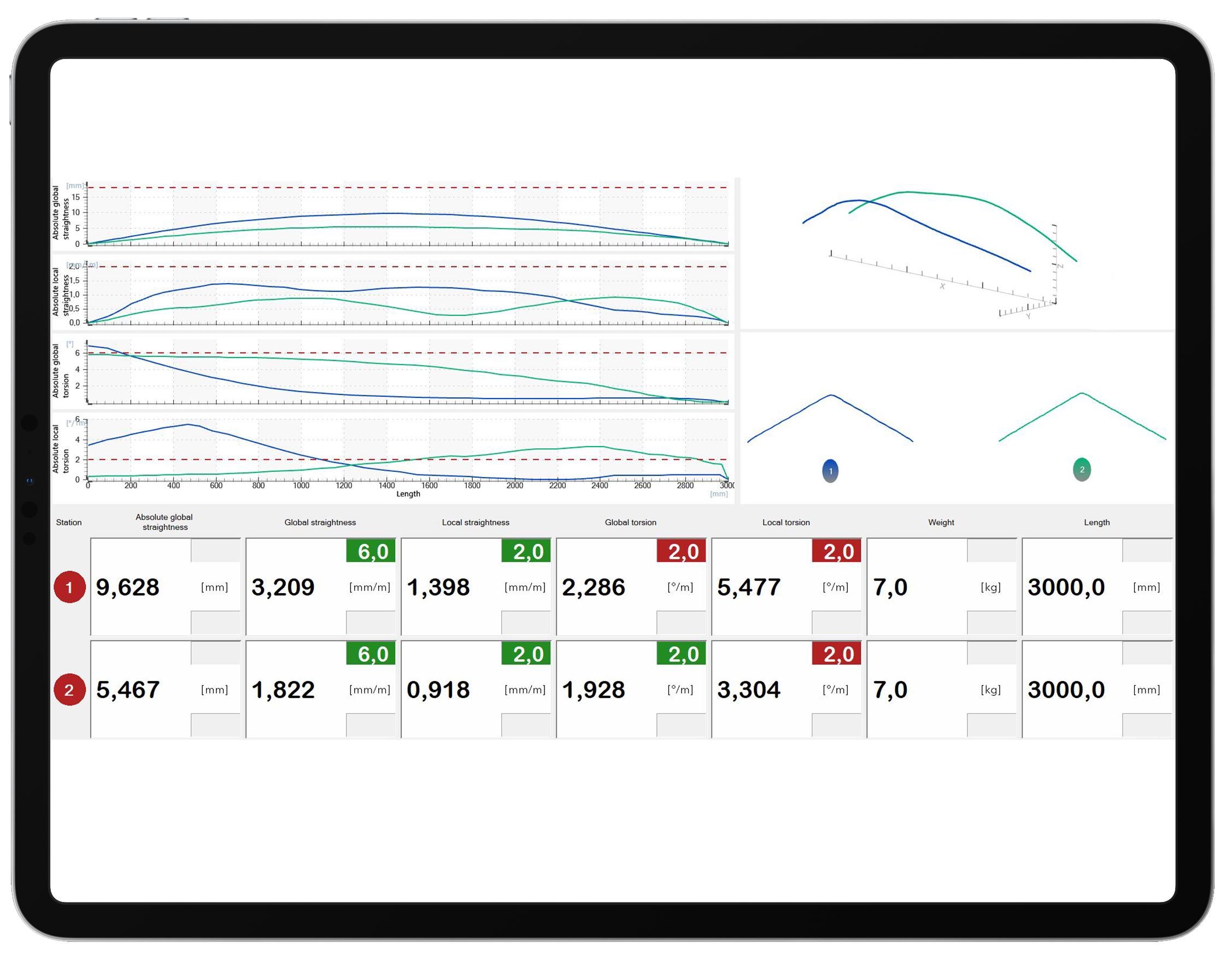

Curve Global Straightness

Distance progression of the workpiece axis to an ideally straight line drawn from the starting point to the end point.

Curve Local Straightness

Course of the light gap between workpiece and adjustable reference ruler at each longitudinal workpiece position

Curve Global Twisting

Angle progression of the profile twist angle from the starting point to the end point of the workpiece

Curve Local Twisting

Twisting angle within an adjustable length section at each longitudinal workpiece position

Measurement place 1

Measurement place 2

Scalar measurement results

Display of the scalar measurement results together with the set evaluation tolerances

2D view

Laser section display of the profiles on both measuring stations

3D view

Effective shape of the workpieces in the heavy lot

With the visualisation of your digital data, you always stay on top of things and can use the information for further processing.

Technical data

Application range

- Digitization

- Product certification

- System control

- Production optimisation in drawing machines

- Production optimisation on straightening machines

- Production optimisation on husking machines

- Machine Learning

Product areas

- Automotive round pipe

- Linepipe (LSAW, HSAW, Seamless)

- Construction pipe

- Profiled rod products

- Steel profiles

Materials

- Steel

- Brass

- Aluminium

- Titanium

- a.o.

Integration possibilities

- Longitudinal transport

- Cross transport

- Standalone

Inspection criterions

- Straightness

- Twisting

- General shape deviation

- Curvature

- Weight

Measuring speed

- 200Hz

Measuring accuracy

- Up to 100µm

Interface

- Process: PLC

- Data: SQL

Downloads

Data Sheet (EN)

Data Sheet (DE)

01/03

Similar machines

Take advantage of our know-how and experience to get one step ahead of the competition. Find more solutions here.