Tuboscan

Pipe measurement at lightning speed

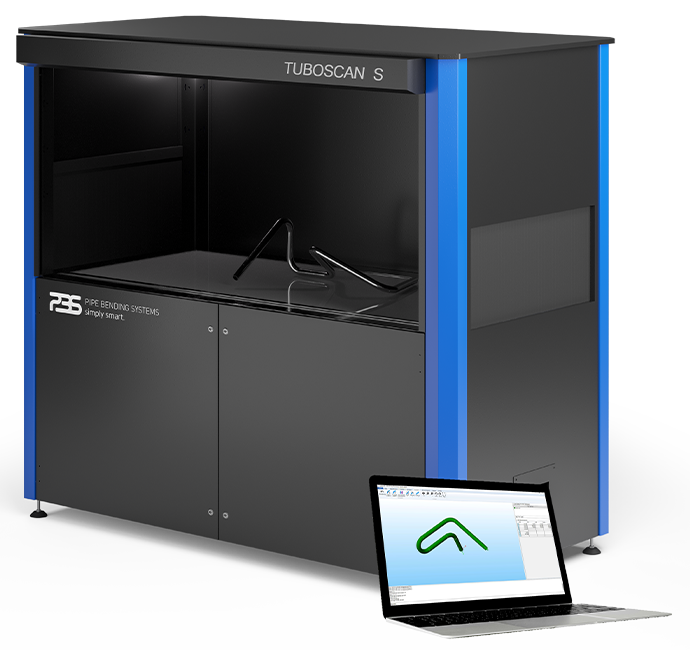

The optical measuring system TUBOSCAN is able to precisely identify the geometrical data of pipe figures within a few seconds.

Measurably precise

High flexibility, low risk

The optical tube measuring system TUBOSCAN S200 ensures quality. The high flexibility allows for the precise measurement and documentation of both pipes with constant bending radii and free-form curved pipes. The system is accordingly suitable for both quality assurance and the correction of bending data.

Various shadow images are generated to evaluate the tube. For this purpose, the measuring cell works according to the method of photogrammetry. High-resolution camera technology ensures particularly precise measurement results. The advantages of the optical tube measuring system TUBOSCAN S200 thus include high flexibility, high quality of the measuring results as well as risk reduction in production and, of course, process optimisation.

Technical data

Application range

- Digitization

- Product certification

- System control

- Production optimisation on bending machines

- Machine Learning

Product areas

- Curved pipes (e.g. hydraulic pipes)

- Curved rod material (e.g. Coil springs)

Materials

- Steel

- Brass

- Aluminium

- Titanium

- Transparent material

- a.o.

Integration possibilities

- Reverse operation

- Manual workstation

Inspection criterions

- Bending radius

- Bending coordinates

- Straightness

Measuring speed

5 Seconds/Part

Measuring accuracy

± 0,1mm

Interface

- Fileexchange

Downloads

Data Sheet (EN)

Data Sheet (DE)