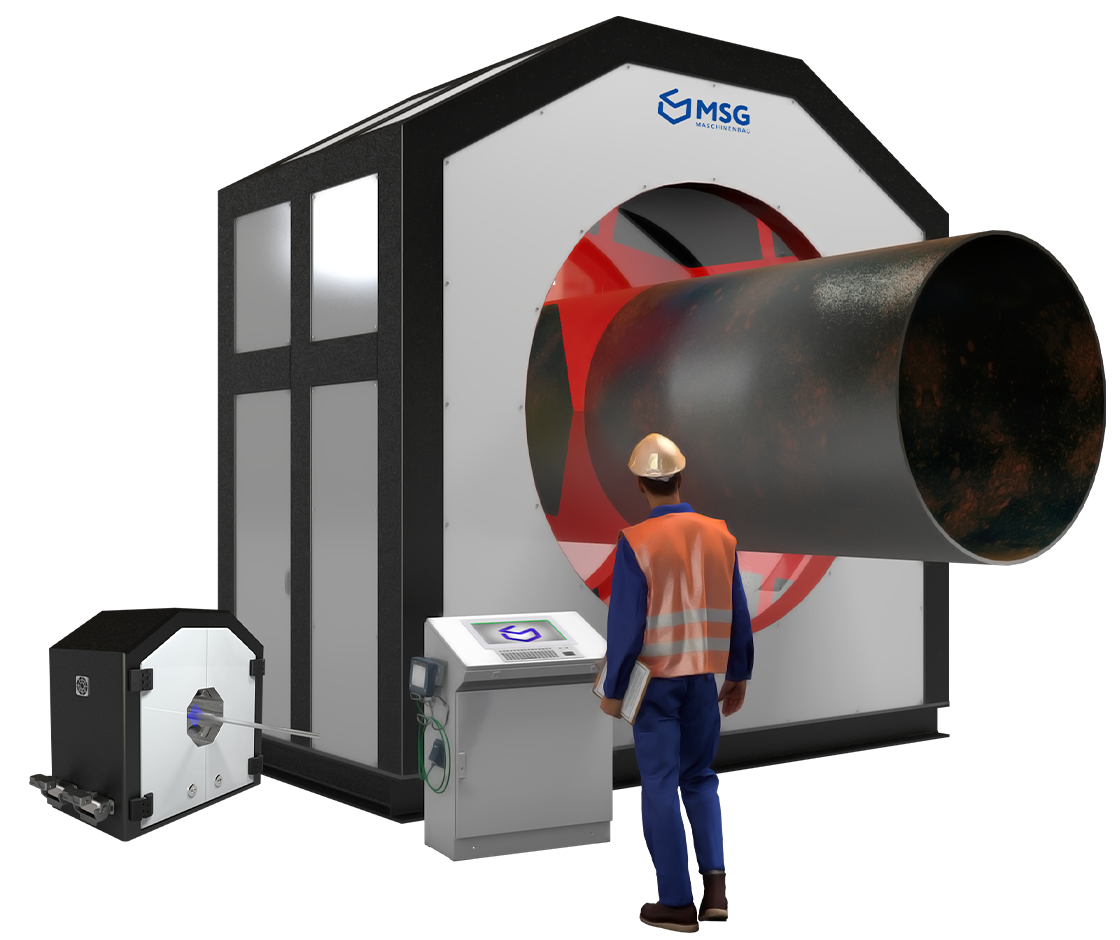

MSG Maschinenbau at a glance

Best partner in the field of machine engineering. We provide our customers with innovative solutions in the field of special machine engineering and measurement technology.

25 YEARS OF EXPERIENCE

Since 1998, we have always strived to find the perfect solution for our customers. Thanks to our own research & development, no customer wish remains unfulfilled. For us, creative design comes by default, and integrating machines into your current production line poses no problem for us.

ONE FOR ALL? NOT WITH US

We believe that customers should not settle for the mediocre. Instead of compromises, customised mechanical engineering solutions constitute our product portfolio. Our excellent vertical range of production and a remarkably strong team help us to achieve this.

YOUR SERVICE PARTNER

“Doesn’t work” doesn’t exist at MSG. Our customer service operates worldwide and is quickly on the scene when needed – ideally, we take preventive action for you. With us, you have one less thing to worry about and can concentrate once again on the essentials: Your production.

Solutions adapted to your problems

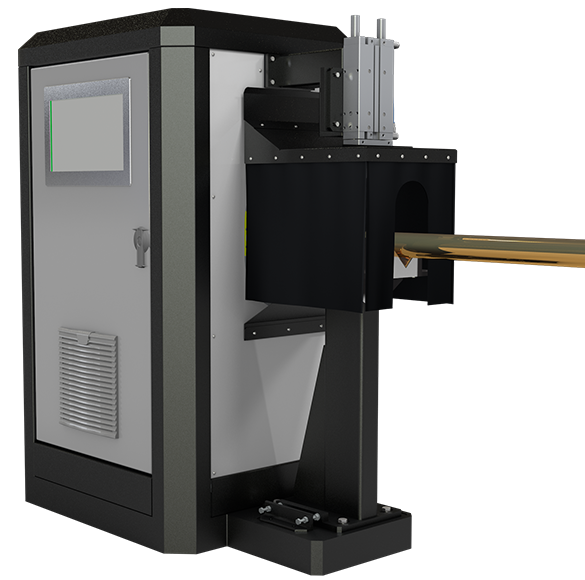

MACHINE ENGINEERING

Complex special solutions are our strong suit. All systems are planned, realized, installed worldwide and commissioned according to the individual customer requirements.

Highest efficiency in your production process with our measurement technology

Straightness measurement

The patented straightness measurement enables the inline measurement of the straightness and twist of profiled rod products.