Production and test line

How to make your production more efficient and of higher quality

Production and testing lines from MSG impress as a complex overall system with efficient output. Fast, reliable manipulation and perfect handling - reducing unnecessary waste and increasing quality standards. The result: simple operation, state-of-the-art measurement technology, comprehensive transparency and process stability in the overall system ensure your calculable success.

Definition of production lines and test lines

What is meant by "production and test lines"?

Production and test lines are the heart of modern production processes. On the one hand, raw materials and components are processed into finished products here (production line). On the other hand, these products are tested for quality (test line).

Our solutions developed in NRW integrate both systems, covering the entire production process from manufacturing to final inspection. And thus maximize the efficiency, precision and product quality of your processes.

Why production lines and test lines are crucial to competitiveness

Your customers want high product quality - and you want to increase your production capacity. Production and testing lines allow you to do both at the same time. By automating your production processes and using advanced measuring technology for quality assurance, you can combine both advantages in a logical sequence.

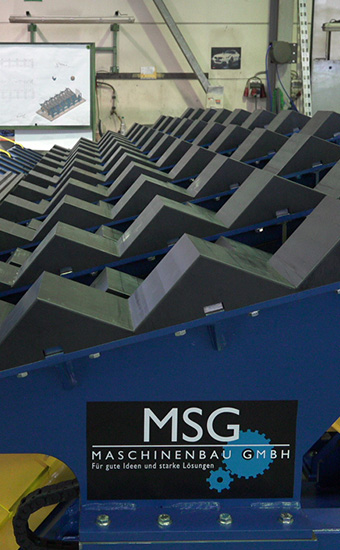

Production and testing lines from MSG Maschinenbau

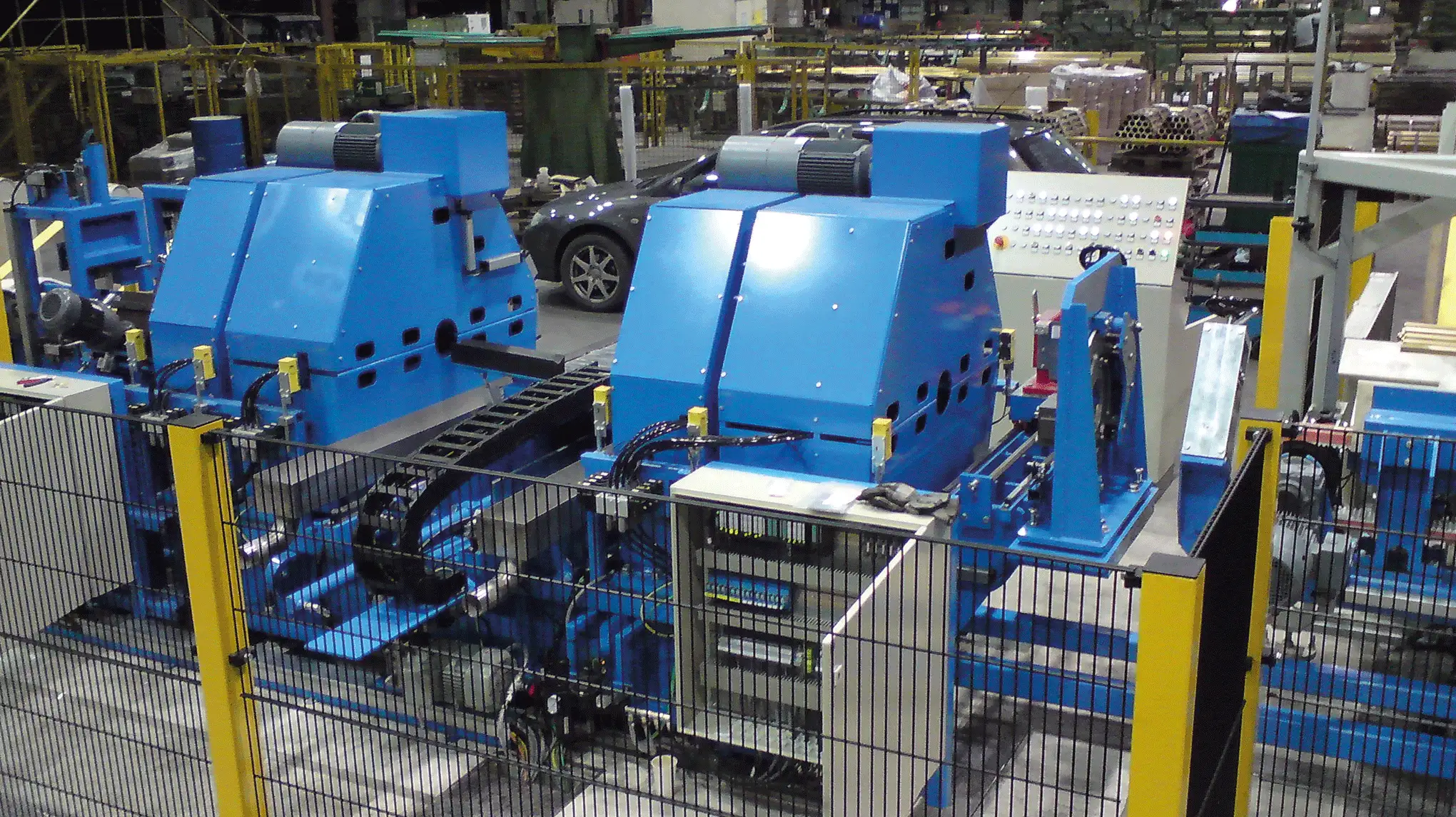

Efficient and automated production processes

We design and implement production lines that are designed for maximum efficiency and throughput. By using robotics and automation technologies, we can optimize processes, increase productivity and minimize human error.

Quality inspection? Simply integrated!

Our test lines use state-of-the-art measurement technology and sensors to monitor and ensure the quality of the manufactured products. These integrated testing systems enable continuous quality control throughout the entire production process and thus contribute to compliance with the strictest quality standards.

Manufacturing and quality assurance the way you need it

We design our production and testing lines specifically according to your needs and specifications. So that you can integrate them seamlessly into your existing production environment. Without long downtimes, for optimum efficiency.

FAQ: Frequently asked questions

What is the advantage of integrated production and test lines?

Integrated production and testing lines improve efficiency and quality. They combine production and quality control in a seamless process, which leads to higher productivity and reduces the error rate.

How can automation be used in production and testing lines?

Automation is used to optimize repetitive operations and processes where precision work is particularly important. In this way, automation reduces the human error rate and increases overall productivity.

Can MSG Maschinenbau systems be customized for specific product requirements?

Yes, our systems are highly customizable and can be developed specifically for a variety of product requirements, material types and industries.

How do you ensure quality in production?

By integrating advanced measurement and sensor technology into our production and testing lines, we can ensure continuous monitoring and assurance of product quality.

Can production and testing lines from MSG Maschinenbau be integrated into existing production environments?

Yes, our solutions are designed in such a way that they can be flexibly integrated into existing production structures in order to expand or optimize them.

What advantages does robotics offer in production and quality assurance?

Robotics offers precision, speed and flexibility in manufacturing and quality assurance, resulting in a significant increase in production output and consistent product quality. Robotics also enables flexible adaptation to changing production requirements and helps to reduce labor costs.

How does MSG Maschinenbau ensure traceability in production?

Our manufacturing and inspection line technology integrates advanced identification and data capture systems that enable complete traceability of every item produced, from raw material supply to finished product.

Can your solutions be integrated with Industry 4.0 technologies?

Yes, our production and inspection lines are compatible with Industry 4.0 technologies and enable intelligent networking within the production environment, resulting in improved processes, increased transparency and optimized decision-making.

How do your production and testing lines contribute to cost savings?

They optimize production processes, minimize waste and increase overall efficiency. Our production and testing lines significantly reduce production costs.

Does your company offer training for the operation of the production and testing lines?

Yes, we offer comprehensive training and support for operating personnel. Take advantage of these offers to ensure that your employees are fully familiar with our production and testing lines. This will increase the productivity and service life of these systems.

Other areas

We offer the right solutions for different requirements. Learn more about our specialisations in the different areas.